Ademar Alexandre Brehmer Rohregger, MBA & BEng Electrical/Electronic Engineering

Address: London, ON N5V 2E8, Canada

Personal Details: Married, Born in Itajai – SC Brazil

+1 (226) 503 4706

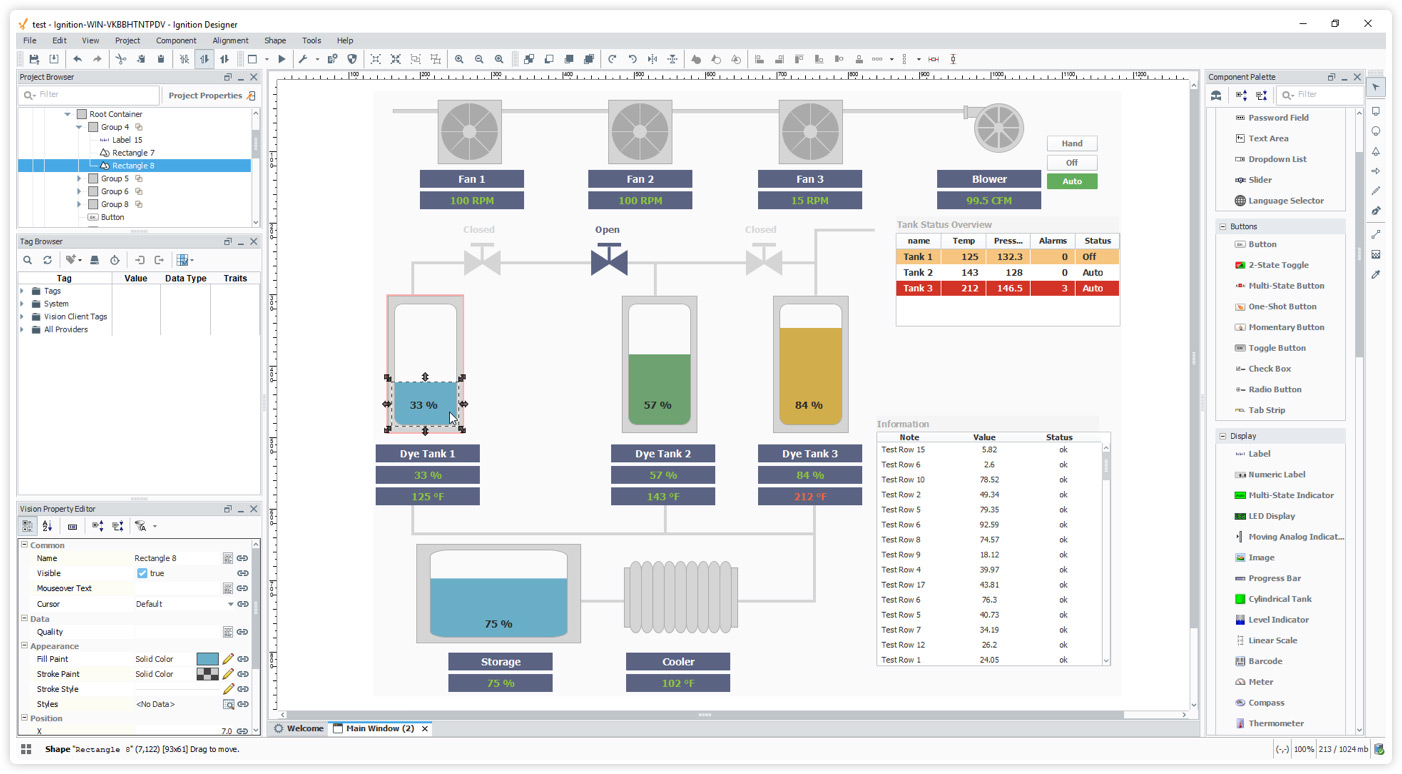

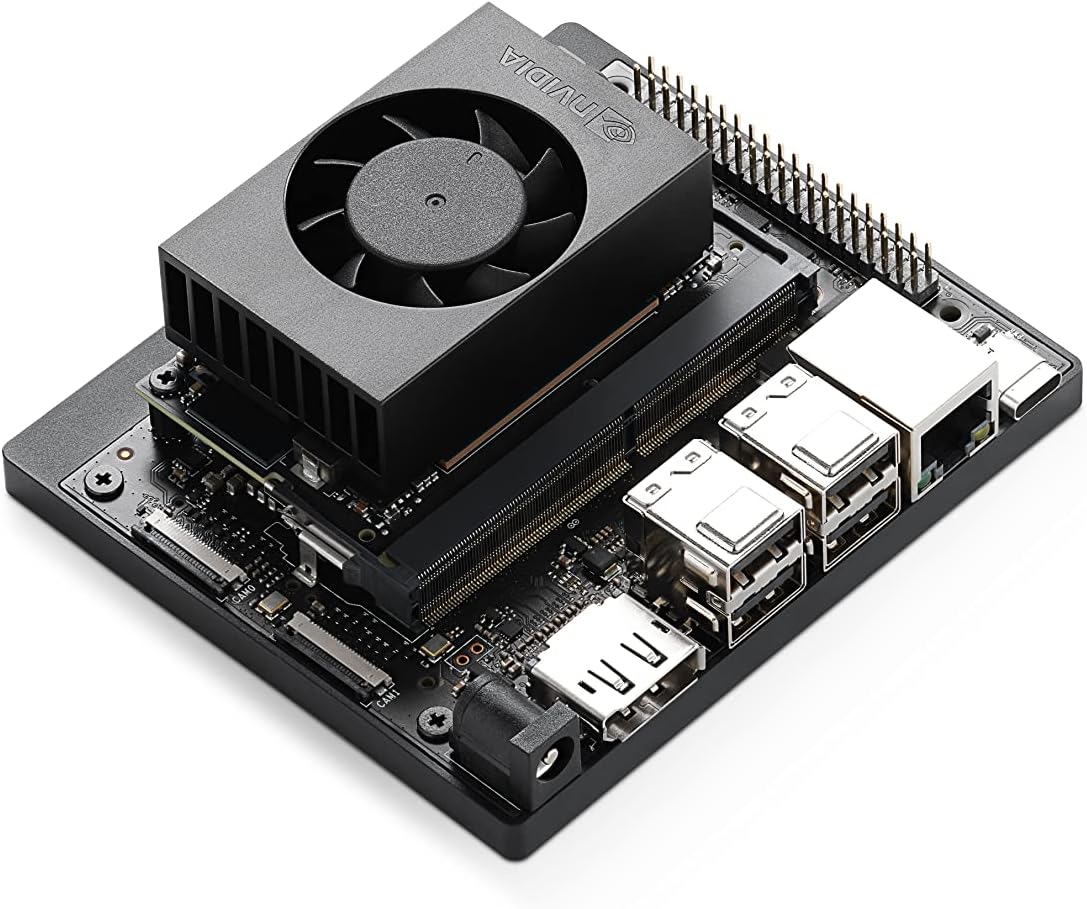

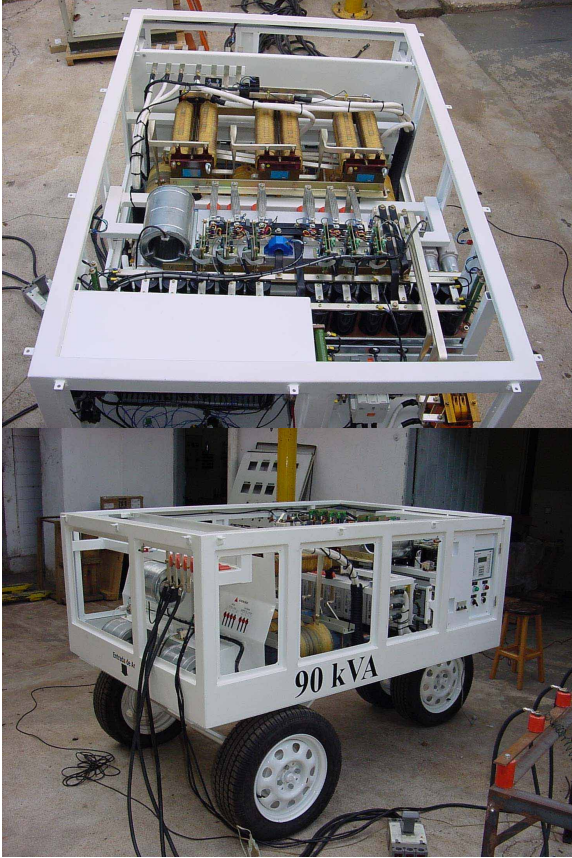

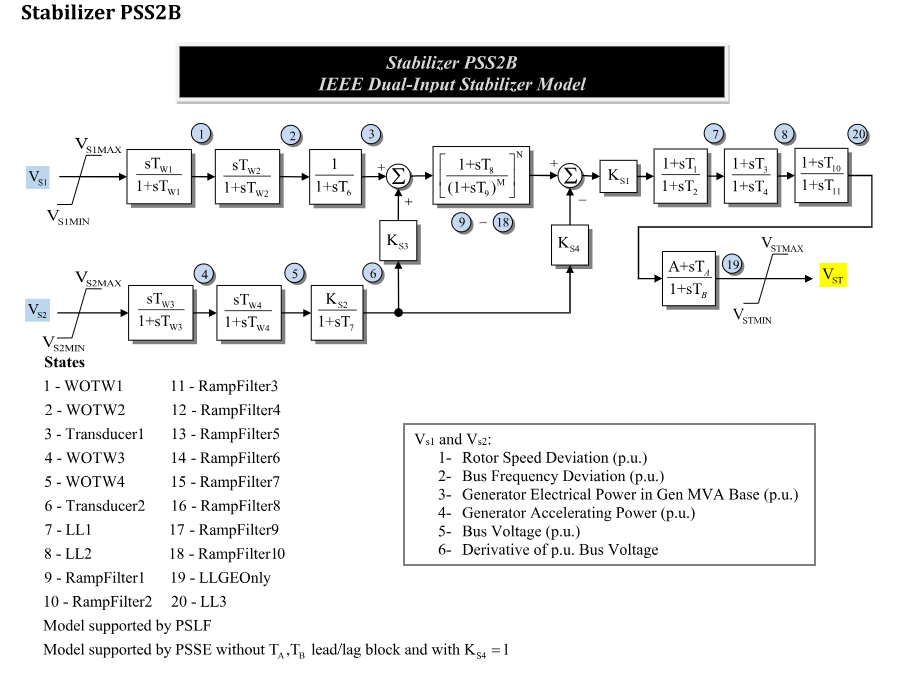

Software Engineer - Control Engineer - Automation / Electrical / Electronic Engineer - Computer Engineering - Computer Vision and AI Engineer

Over 15 years of basic and executive project experience

Over 36 years of technical background

Over 26 years of automation / electrical / electronic engineering experience

Over 11 years of IT experience

Over 15 years of basic and executive project experience

Over 36 years of technical background

Over 26 years of automation / electrical / electronic engineering experience

Over 11 years of IT experience